- #LIFT LUG DESIGN GUIDELINE MANUAL#

- #LIFT LUG DESIGN GUIDELINE FULL#

- #LIFT LUG DESIGN GUIDELINE VERIFICATION#

#LIFT LUG DESIGN GUIDELINE FULL#

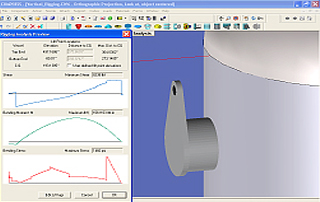

The verifications of the previous case are repeated with the additional verifications of the connected bottom section to the bending effect produced by the eccentricity of the force.Īlso for this case two welding types are included: fillet weld and full penetration weld.ĭesign of a lifting lug with overlapping plate joint subjected to a sloped force Lug with an applied force having an assigned sloped angle and eccentricity with respect to the hole. Lifting Lug subjected to a load with given slop e Metric (S.I.) or English (U.K.) Units System can be selected for the calculation. Useful graphical views of the lug and welding are foreseen to better define the geometry and the dimensioning parameters.

Two dimensioning welding cases and configurations:

#LIFT LUG DESIGN GUIDELINE VERIFICATION#

#LIFT LUG DESIGN GUIDELINE MANUAL#

Ricker, PE, AISC Engineering Journal, Fourth Quarter/1991 and its updating to 2005 AISC Manual of Steel Construction (click here to download it). The verification is performed considering the reference 'Design and Construction of Lifting Beams' David T. This guide is intended to help the user include safety in the planning and actual practice of rigging mechanical industry equipment and materials for lifting operations.ĭifferent worksheets are reported for a complete verification of common configurations. Perform their rigging responsibilities more effectively. Prevent damage to equipment, materials and property and. Prevent rigging/lifting related injuries. 2.2 It covers lifting operations by floating crane vessels, including crane barges, crane ships, semi. GUIDELINES FOR MARINE LIFTING & LOWERING OPERATIONS 0027/ND Rev 11 of 84 2 INTRODUCTION 2.1 This document provides guidelines on which the design and approval of marine lifting operations may be based. ' Pressure Vessel Handbook ' By Eugene F.Suggest You Take A Look At The R002 Norsok Lifting Equipment Document As Guidance/reference.\r Not Sure If The PIP Standards Also Might Have Something For This. You May Want To Review DIN 28085 And/or DIN 28086.

The spreadsheet verifies some configurations of lifting lugs and padeyes.

0 kommentar(er)

0 kommentar(er)